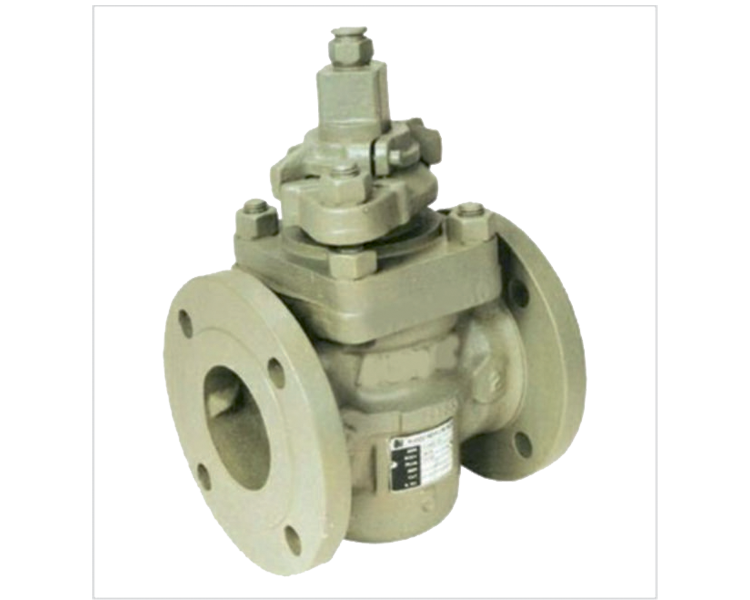

FORGE STEEL BALL VALVE DESCRIPTION

Features: 3 Piece Reduce Bore, Design STD.: BS EN ISO 17292 (BS 5351), Testing STD.: BS EN 12266-1 (BS-6755- PART-1)

Optional Features: Full Bore, Antistatic Device, Metal to Metal Seating, Nipple Extension

On Request: Fire Design Safe As Per API-607, Jacketed Valves, Extended Spindle for Cryogenic Service, Locking Arrangement, Stellited / Hard Faces, NACE As Per MR-01-75.

Pressure Ratting/Class: 800#, 1500#, 2500#

End Connection: Socket Weld, Screwed BSP or NPT, Buttweld, Welded Flange.

Size: 15MM to 50MM

Material of Construction (MOC): A105, LF2, F304, F304L, F316, F316L

Seat Material: PTFE (Teflon), CFT, GFT (RPTFE), PEEK, Devlon, etc.

Trim: SS304, SS316, SS304L, SS316L, Monel

Other Grades On Request: F5, F9, F11, F91, F321, F347, Alloy-20, Super Duplex, Nickel Alloy, Monel, Hastelloy, Inconel, SS904L etc.